Artificer Dice v4.0 Dev Log 3 - Rough Draft + ECAD

I have been jamming out the physical specs of the Artificer Dice model pretty rigoroulsy over the past few weeks. I picked up a few new techniques in Fusion 360 that have really streamlined the design process, and am immensely pleased with how it is all turning out.

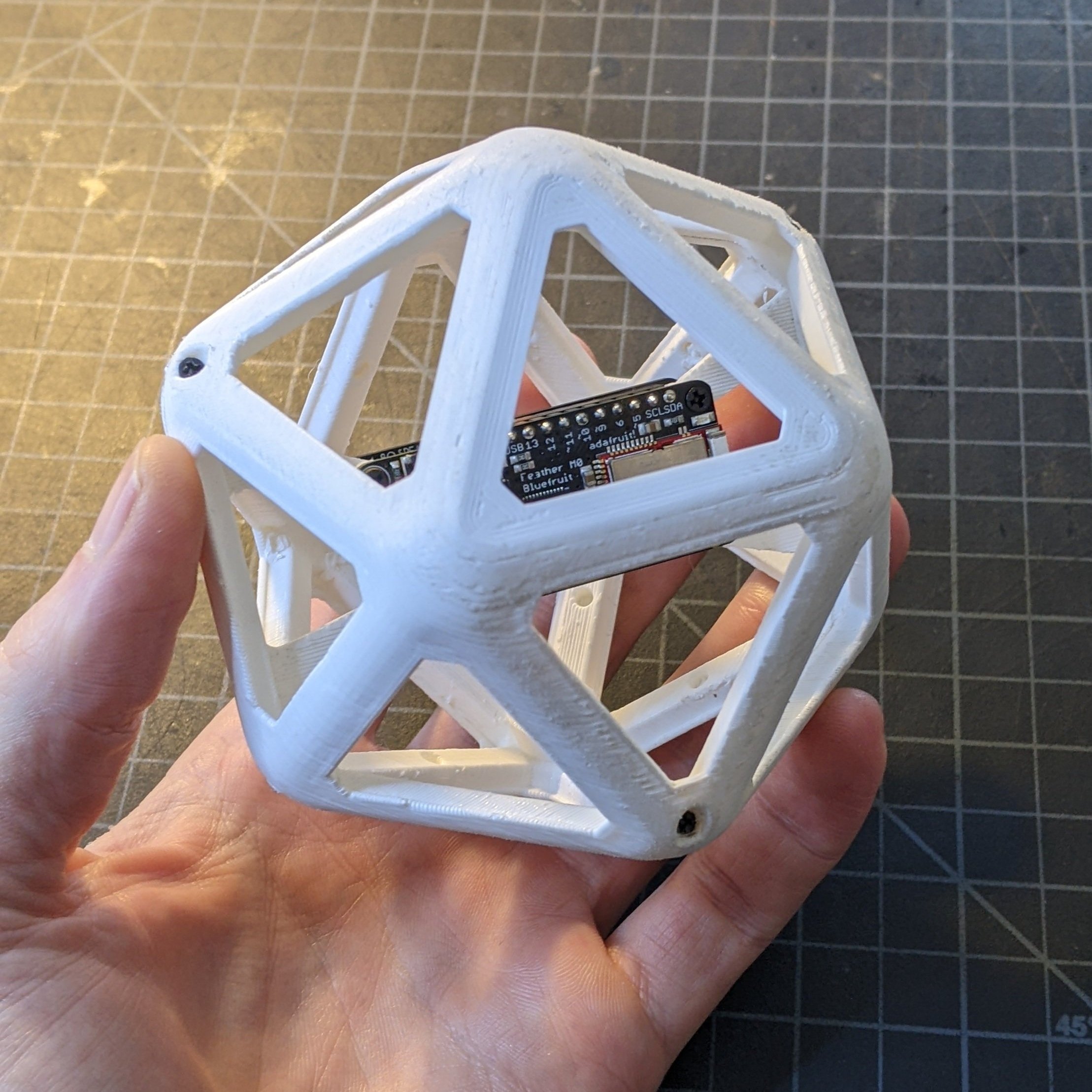

Inner workings so far. Everything fits, and getting a little unconventional with the PCB design and implementation.

The scale is absolutely bang-on. The previous cardboard prototypes worked well in getting a sense of scale and feel. Hopefully I will be able to continue with this size.

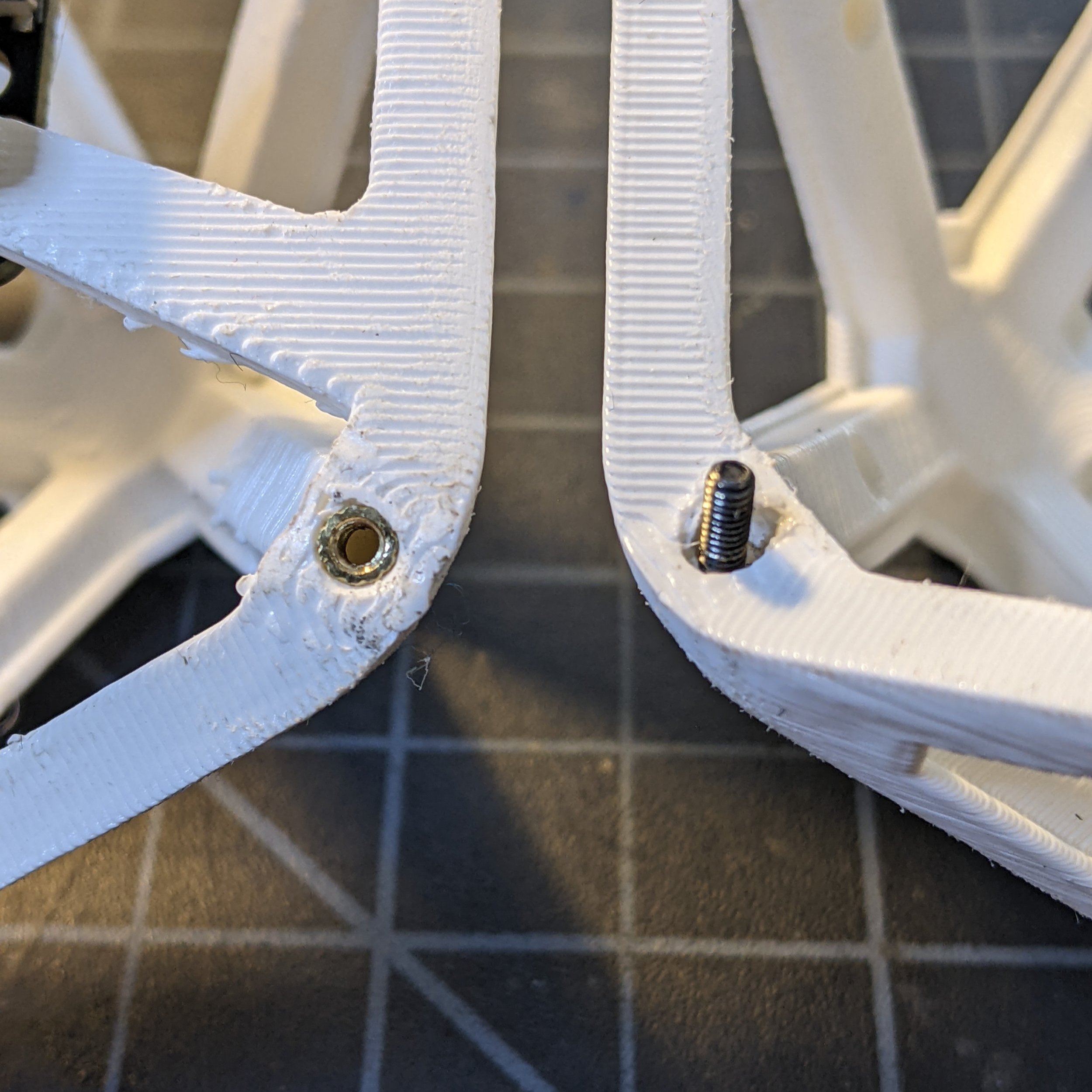

After spending last week working with a Robotics Lab I learned how to use threaded heat-set inserts with 3D printed parts. This was a logical addition to the prototype, as I was initially planning on just threading right into the plastic. After a quick print I did a dry fit of some of the components to see where I stood; it was immensely informative to be able to hold it in my hand and see the physical parts in the frame. I find I lose track of the scale of things when doing CAD.

Nevermind the abject messiness, turns out the print was a little thin and warped a bit when introduced to the hot metal bits.

My newest adventure is grappling the ins-and-outs of Fusion’s ECAD interface. I have some ECAD experience with Eagle, which is essentially the same program, but Fusion packages everything up nicely to incorporate fully modeled boards into assemblies. So far I have a slick two-sided PCB designed to make what I’m calling a “Hybrid” LED strip of PCB’s connected with ribbon cable. Ideally I would be using a flexible PCB, but they are roughly 10x the price of conventional PCB’s. I can already hear my old boss telling me I’ve lost my damn mind over this...

These double-sided PCB’s will allow me to make a serial LED strip that can curve at specific angles to create the folded structure. I’m still a novice at ECAD, so it’s not perfect, or visually messy…

Coming up next: finalizing the PCB design, getting the models SLA printed, and getting to know the Adafruit Feather M0 BLE and Prop Maker!