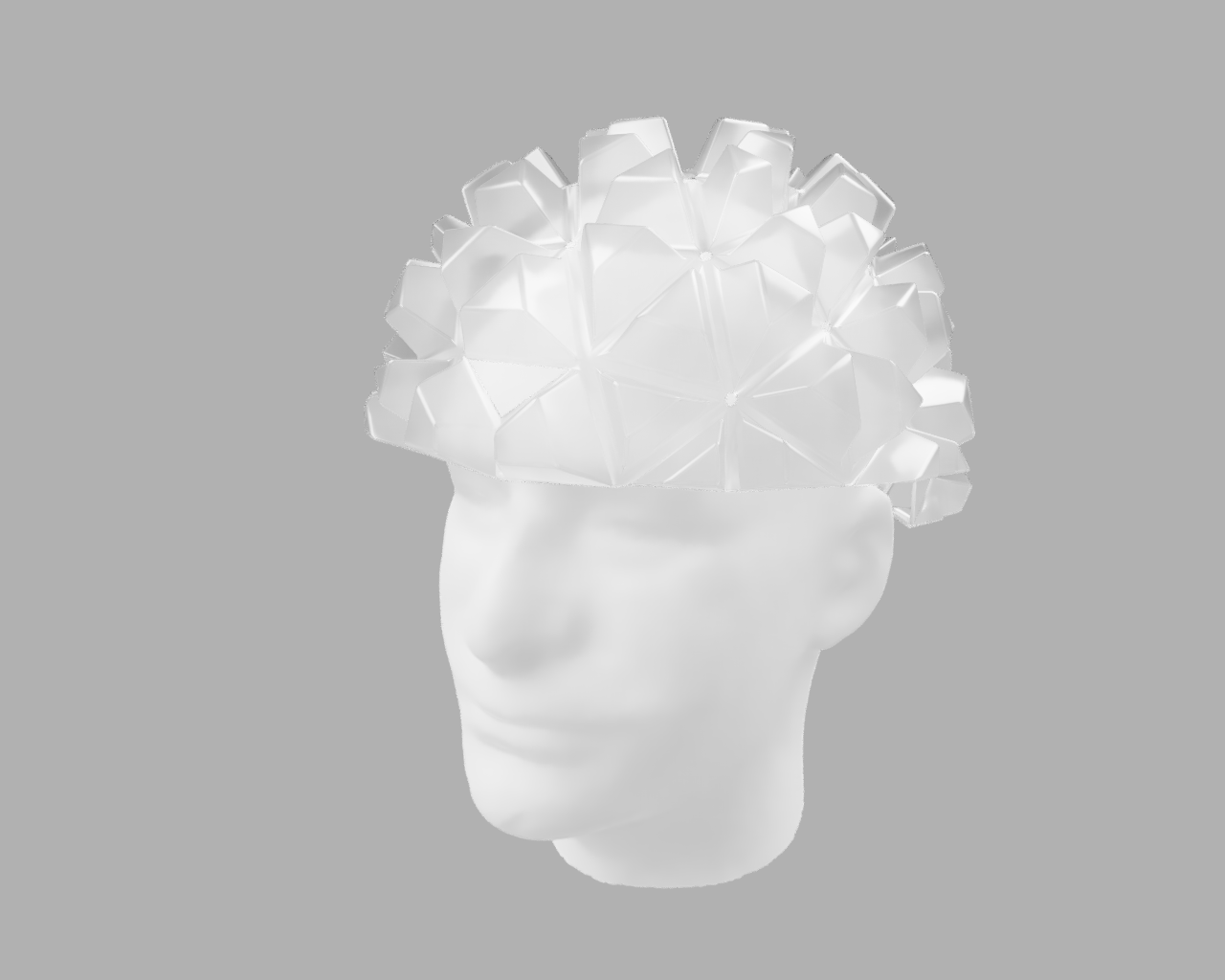

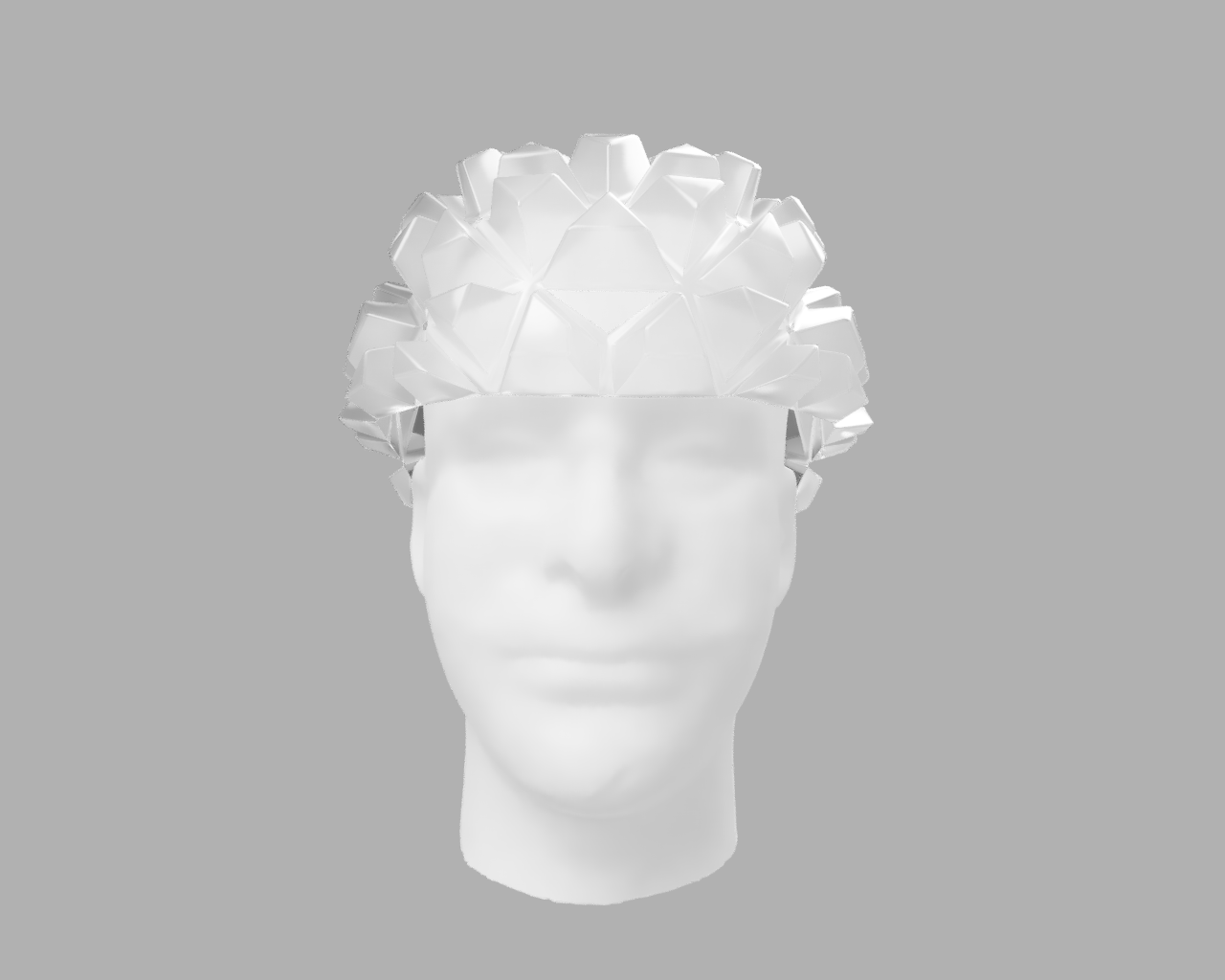

IMPACT CELL LINER

2021 (Ongoing)

My EPS-free impact liner was largely informed by Prof. Tso Liang Teng from Hsiuping University of Science and Technology Dept of Engineering, who wrote numerous papers on the superior impact protection of cellular conical liners compared to EPS. All of his data, however, came from simulations—not physical testing, as there was no mention of production methods outside of material specs and thickness. Upon looking at his designs I realized their potential to be created using thermoforming—a process used to make the upper and lower shells of helmets.

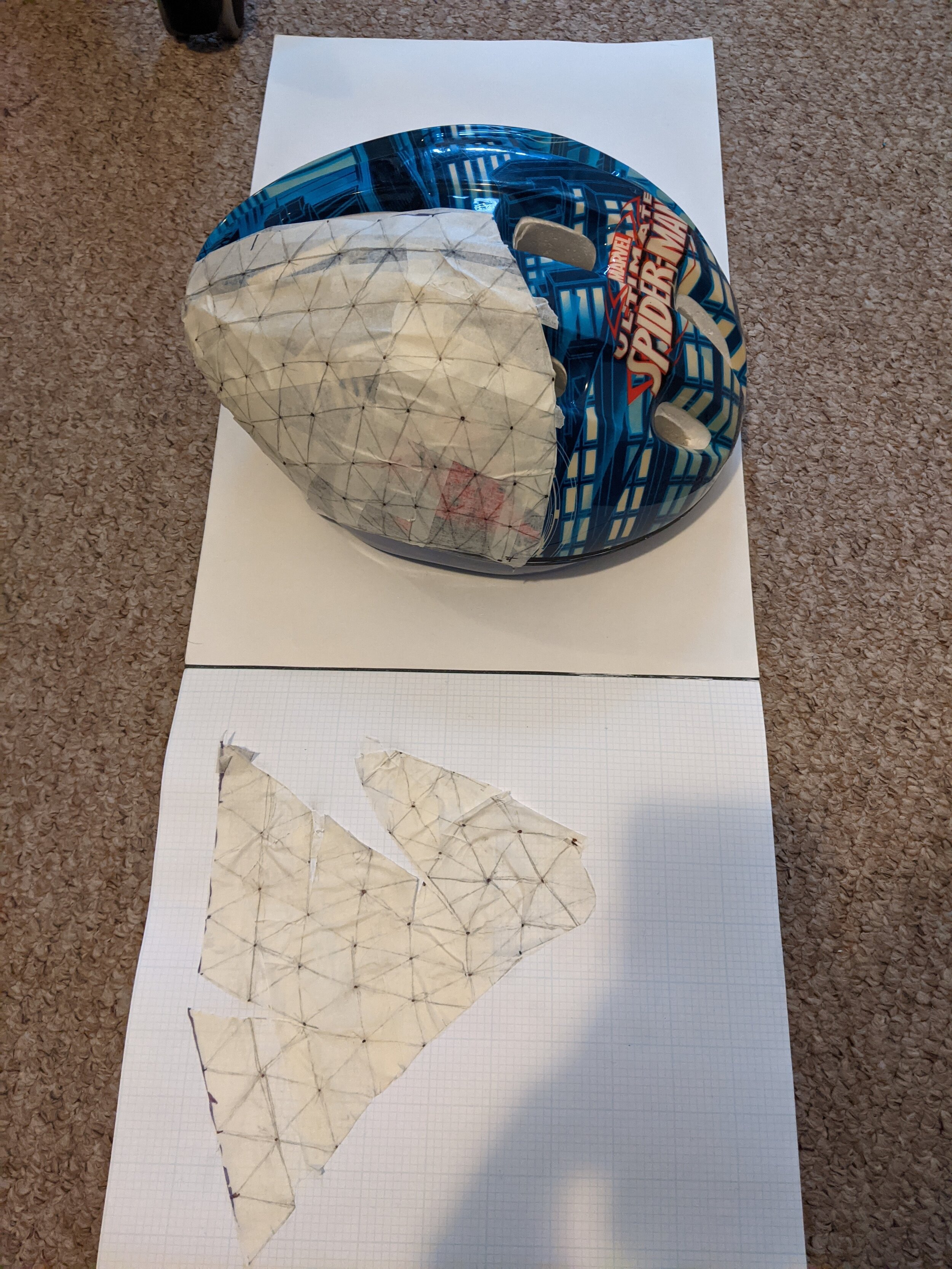

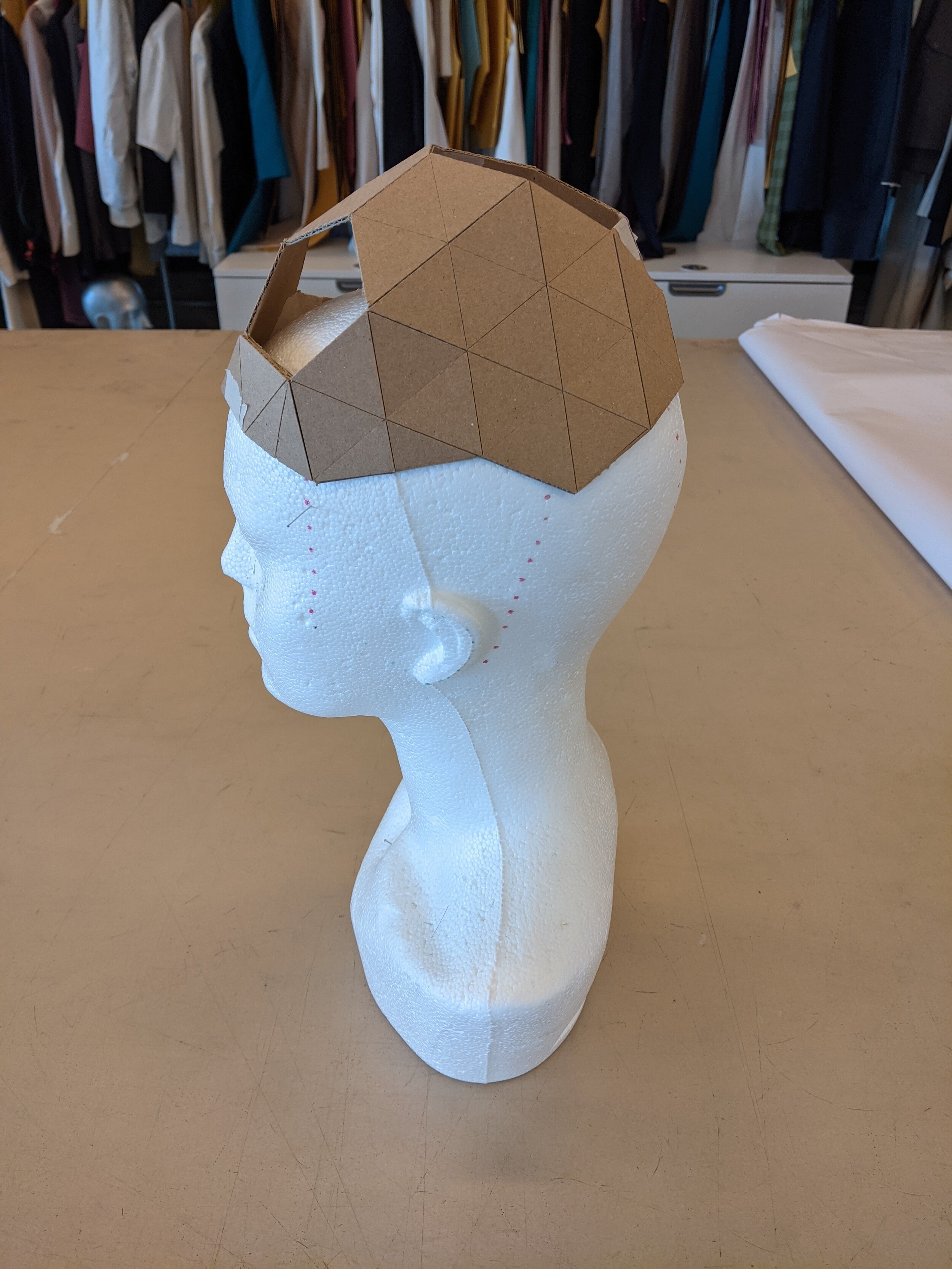

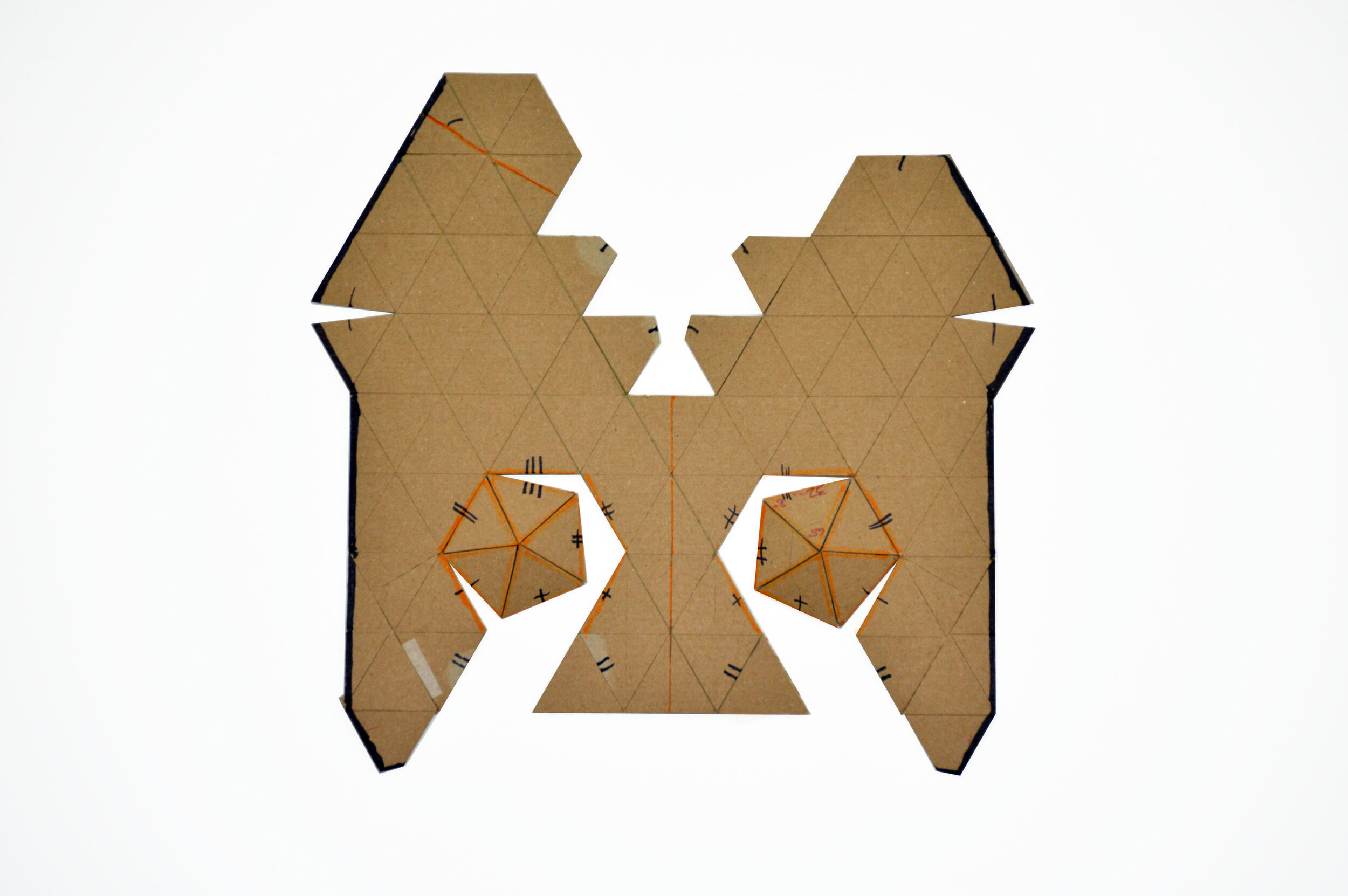

I consulted with one of the Fashion Technicians at the RCA to drafting such a pattern. Not long after I sat down with a sheet of thin cardboard scored with triangles and began solving for

a potential net structure.

While mulling over the cellular liner concept I had spotted something interesting at some souvenir kiosk in Camden;

a collection of trendy bags with a faceted triangular design.

“Of course!” I thought to myself, “triangles!” I observed how they could contour to the fluidity of the fabric, and thought that might be a suitable approach to designing a liner. It wasn’t long after I realized how closely it resembled some of my earlier thermoform work with the folding icosahedrons.

With the flattened net resolved it was a simple matter to turn it into a mesh into CAD. While the cell topology may change with future iterations, the net could more or less stay the same—and it’s only a sheet of cardboard away from another design.

Ultimately the singular-piece liner may be more trouble that it is worth in the long-run. Folding hinges have worked in the past, though may not be suitable for high-impact applications. I suppose I won’t truly know the answer until I am holding a testable prototype in my hands…